Thermal imaging cameras are handheld instruments that measure the heat differential of objects in the view of the camera. Like most technology, capabilities are getting better and better, as well as more affordable than ever, like the pocket sized smart phone attachment, the FLIR One, which we wrote about recently. Thermal imagers have many great applications in the construction industry, which not only help you determine the quality of your build, but also can greatly assist in preventative maintenance. Contractors provide warranties for their work, so it could save a lot of time and money if problems were caught before a catastrophic failure happened.

Below is a list of ways to use thermal imaging cameras on the construction job site:

Electrical Inspections

Improper electrical installation can cause extremely costly repairs later on, but with a thermal imaging camera, a contractor can detect problem areas in an electrical panel before they cause issues. As highlighted in the video below, by Keysight General Purpose Instruments the camera points out hot spots in the panel, which could be caused by overloading the circuit or loose or damaged wires.

Heat Loss/Air Infiltration

Energy efficiency is all the rage in the construction world and nothing hampers energy savings more than heat loss and air infiltration in a building. With the use of a thermal imager, contractors can detect areas where insulation and seals have been missed, which could otherwise cost them a ton of time or money trying to diagnose issues without the technology. The beginning of the video below, by Arkansas Living, shows how to determine if an area is missing insulation.

Roof Leak Detection

Roof leaks are extremely difficult to find and cause a lot of heart ache to the building owner. The video below, by AM Leak Detection in Ireland, explains that water retains heat much longer than surrounding surfaces, making it much easier to see where moisture has collected and which areas to attack first.

Plumbing Blockages

Most plumbing issues develop over time and can cause very costly repairs. Drains are a quick and easy way to get rid of job site debris and trash, but that causes major blockage in plumbing lines. The video below, by FLIR one, shows how running hot water through the drain lines can show you exactly where the blockage is occurring.

At Milwaukee’s New Product Symposium in June of 2017, the company then showed their commitment to the 12-volt platform with the announcement of the Generation 2 M12 Hammer Drill and Impact Driver. The hammer drill and impact driver were since released in January 2018 and we’ve had the opportunity to test the tools for ourselves. The drill/driver is yet to be released as of the publish date of this article.

Smartphones have replaced a lot of different objects and materials on today’s construction site. They’re used for pictures, video and audio recording, and note taking, among many other uses. Beyond the typical functions most phones already have incorporated within them, there is now a significant market of accessories designed to make your phone even more useful on the construction jobsite.

We’ve compiled a list of 5 different accessories that you can buy to further enhance the power of your smartphone for construction.

Painters are typically one of the last subcontractors on any construction site, who do their best to beautify the drywall with the colors of the architect's or interior designer's choosing. Some painters are also responsible for mudding drywall, patching holes, sanding, and caulking.

Let's take a look at how an average painter's hourly wage compares in each state...

In doing the research for this analysis, I learned something interesting about the plumbing profession. The term "plumber" comes from the Latin word "plumbum," which means lead. Seems fitting in a profession, fairly or unfairly, stereotyped for exposed butt cracks.

In Roman times, plumbers often worked with lead for conduits, drain pipes, and making baths. Plumbers now work with a variety of different materials, including copper, PVC, ductile iron, among others.

In January of this year, tragedy struck a Florida construction company when 3 construction workers died while working underground below a newly paved road. After the first worker entered the hole and collapsed after entering the confined space through a manhole, the second went in to rescue him and also collapsed, followed by the third. After a post-incident investigation, OSHA has released their findings, as well as several fines.

This is a guest post by Bob Wells, a retired HVAC tech who now dedicates himself to sharing knowledge on his website hvactraining101.com.

No matter what our specialty, once we’ve been on a construction-related job a few years, we’ve got a few stories to tell. A lot of them start with “How the he**” did that get there, or “YUCK!”

The 2017 Milwaukee Tool New Product Symposium (NPS) was held last week at Milwaukee’s headquarters and it proved to be a whirlwind of new products and information from the red brand. Over 80 new tools and accessories, which will be released throughout the remainder of 2017, were presented to dozens of media representatives, including construction magazines, YouTubers, Instagrammers, and your favorite construction blog (Construction Junkie, obviously).

After flooding our social media pages with Milwaukee information and gathering our thoughts from the event, we’ve come up with our 9 biggest takeaways from the event, in no particular order.

Announced at the start of the new year, FLIR has released specs on its new and updated line of thermal imaging devices and accessories. We have talked about the many reasons that contractors should use a thermal imaging camera and the FLIR ONE mobile accessory in the past and it has returned in 2017 with a new Gen 3 Pro Model. They have also announced their FLIR C3, which is the size of a standard digital camera, offering great accuracy and detail in a compact form. Lastly, FLIR is also offering the FLIR Duo, which will remind you of an action camera. Intended to be used on that fancy new drone quad-copter you got your kids for Christmas.

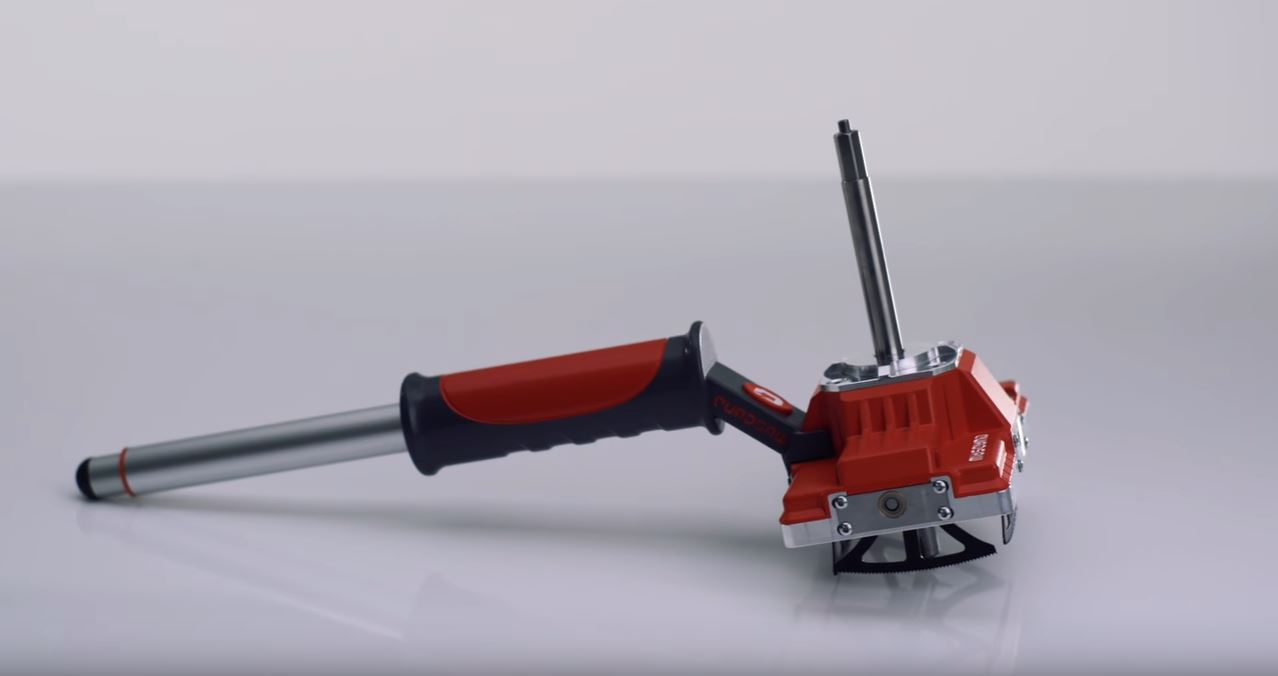

Once again technology has made our old proverbs obsolete, take the old “square peg/round hole” saying, for instance… I’m sure there’s a joke in there somewhere, but I can't find it. Currently your choices for hole saws and drill bits are round and more round, so those pesky square holes that need cut for electrical boxes require a jab saw or a router. It’s not terribly difficult to cut square holes using those methods, but, one company has taken it upon themselves to make the process much quicker.