We’ve mentioned it over and over again, but construction rework is expensive, time consuming, and wasteful. This is especially true when the rework involves the world’s favorite building material, concrete; as hard as it is to put in, it’s even harder to take out. Because of that, it’s extremely important to develop good practices to spend time planning before a concrete pour.

Dan Henrie, an experienced superintendant and creator of the website Constructorator, recently detailed the important information that needs to be logged before a successful concrete pour. In his post titled “Why You Should Be Using Pre-Pour Cards On Your Next Concrete Pour,” Henrie suggests logging the “Who, What, When, Where, and How” of the pour. Below is an excerpt from his post:

Who: has verified, inspected, checked, and figured: yardage, elevations, sleeves, anchor-bolts, embeds, reinforcing, elevations, mix design etc.

What: is being placed, size of pour, manpower needed (footing, wall, column, SS, SOG, S.O.M.D)

When: is the pour happening (Date, Time, truck spacing)?

Where: (Placement location, pump truck setup, truck route, wash out bin)

How: is it being placed (pump, screeds, equipment, lighting, safety, etc.)?

The most important factor in a successful pour, he says, is the not the actual documentation of this information, but the thought that went into creating and following the procedure. However, documentation is always a good thing, as it can save you from potential liability in the end.

Henrie also created an interactive Pre-Pour Card Example on his post, which you can access here, or by clicking the button below. He even offers to help those needing a custom card for their company. We’re a big fan of logging data at Construction Junkie, because it helps build a complete history of a project and can quantify potential opportunities.

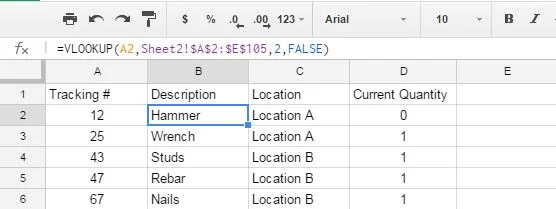

Much like with our DIY inventory process, we would suggest taking the card a step further and creating your Pre-pour card using a cloud based platform, like Google Forms, which can keep all of the data from each of your concrete forms on one spreadsheet and be accessed from anywhere for easy reference.

Why You Should Be Using Pre-Pour Cards On Your Next Concrete Pour | Constructorator

Last summer, Hilti announced that they had developed their first exoskeleton designed for construction tradespeople in a partnership with Ottobuck, a prosthetics, orthotics, and exoskeleton provider. Earlier this month, Hilti officially released the exoskeleton, announced more details, and published its retail price on their website.

Cat Phones is known to make some pretty rugged smartphones, the kind of phone you don’t have to worry about on the jobsite – even without a case. Licensed by the construction equipment giant, Caterpillar, the phones are made by the UK-based Bullitt Group. The company recently announced the release of their new flagship smartphone model, the CAT S62 Pro.

Father’s Day 2021 is June 20, so you better get started on gift ideas if you want to impress dad this year. Whether your father is contractor, handyman, or DIYer, we’ve got a lot of great ideas for him this year.

For more more gift ideas, be sure to check out our past Father's Day Gift Guides from 2016, 2017, 2018, and 2019 or our Ultimate Construction Holiday Gift Guides from 2015, 2016, 2017, 2018, 2019, and 2020

Lithium battery technology is being pushed to new heights in the tool world seemingly every month, as more power hungry tools continue to drop the cord and join the battery revolution. DeWalt is the latest in the game to up the ante with the release of the first 15 am hour 18V battery on the market.

While still new in the construction industries, robots are typically designed to perform a specific task in a highly precise and efficient way, like the rebar tying robot, Tybot or the brick-laying robot Hadrian X. More recently, though, robots are being imagined as platforms for 3rd party companies to develop hardware and accessories to attach to the base robot, like the Boston Dynamics robotic dog, Spot. I recently came across a new robot, called Baubot, which hopes to one day perform tasks using every tool on a typical jobsite.

Those that follow tool news may have heard about a new Makita tool platform that launched in several other countries a few months ago and have been waiting for the news of it finally being released in the United States. Well, the wait is over, as the teal tool brand has finally announced the release of their 40V and 80V XGT system in the US.

“You make a better door than a window!” is what I imagine loader operators constantly yell at the bucket in front of them (or maybe I’m just projecting based on my experience of having the habit of sitting right in front of the TV as a kid). Either way, operators may not be yelling that in the future, as equipment manufacturer, Doosan, has introduced what they claim is an industry first “transparent” bucket.

Reducing dust when cutting tile is important for many reasons (including safety and cleanliness), but wet tile saws can be a pain to use, with the slurry created spraying all around the work station and cold weather making the saw much more difficult to use outside. iQ Power Tools has a solution for that: the world’s first 7” portable dry table saw with integrated dust control.

Just over a year ago, I was introduced to an early prototype of the SkyMul SkyTy, which is a robotic drone with a rebar tying attachment designed to autonomously locate and tie rebar on the jobsite. After a year of tweaks and advancements, SkyMul is now on their third prototype and they showed off those improvements in a new video.

Like most of the other electric machines that have been announced previously, Volvo promises that this midsized, 14 metric ton excavator will have the same performance as a similarly sized diesel version. The X03 is currently in the concept stage, so Volvo does not have immediate plans to bring it to market, but it shows the possibilities that electronics on heavy machinery can allow for.