Just over a year ago, in September of 2017, Hurricane Irma blew through Miami, Florida, bringing extremely high speed wind with it. The wind caused 3 cranes to collapse in southern Florida, 2 in downtown Miami and 1 more in Ft. Lauderdale. Interesting video of the dismantling of one of the failed cranes was shared on Youtube.

After being referred to go to the sites of the failed cranes by the media, OSHA was originally only going to help in the safe dismantling of the cranes by providing technical assistance. According to their recently published report, titled “Investigation of the Failures of Three Hammerhead Cranes on September 10, 2017, in Miami and Fort Lauderdale in the Wake of Hurricane Irma,” OSHA later suspected possible design deficiencies in the model of cranes that were used in all 3 sites, so they decided to open an engineering investigation.

All 3 cranes that collapsed, according to the report, were model number SK 315. Two cranes were manufactured by Noell Service and Maschinenetechnick GmbH (Noell) and the third was manufactured by Terex Peiner GmbH (Terex Peiner). There was also a fourth SK 315 model crane in the area that did not collapse, but the report states that it was at a much lower height and also shielded by tall structures. There were at least two dozen other cranes in the area that did not collapse.

To conduct their investigation, OSHA’s Office of Engineering Services (OES) visited the construction sites where the incidents occurred, Maxim Crane’s storage site in Kentucky, and the location where the remnants of the failed cranes were stored in Orlando and Miami.

In the report, OES concluded that the cranes were manufactured to withstand 95mph winds at the jib level and the manufacturer’s manual mentioned that failure could occur in wind speeds exceeding 95mph. The manufacturer’s instructions also state that, if winds exceed 45mph, the crane must be taken out of service and allowed to “weathervane,” or freely swing with the wind. Neither the US nor European codes require that turbulent wind, suction, or vortexes be considered into the crane’s design.

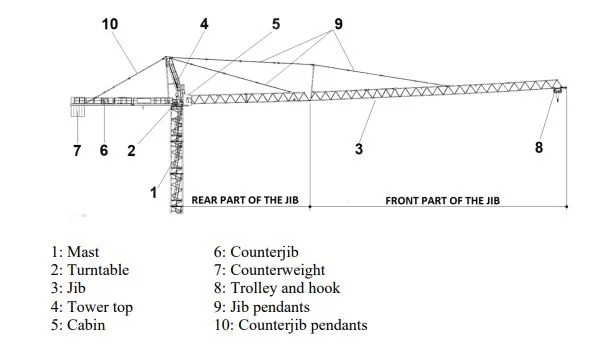

OES determined that the cause of the 3 collapses was the model’s inherent weakness at the connection of the jib to the turntables. The report states, “The cause of the failure of the three cranes was the detachment of the crane jibs from their turntables due to turbulent wind loads. Based on our evaluation, it is believed that wind gusts, at oscillation periods corresponding to the frequencies of the dominant modes of the jibs, struck the jibs. Under the turbulent wind loads in either lateral or upward direction, the forces on the turntable cradles at the jib feet exceeded their capacities. The separation of the jibs at the turntable caused the jibs to fall in all three cases.”

SK 315 crane, via OSHA

The report recommends that local governing bodies in areas with tall buildings that are also prone to turbulent winds, should consider additional analyses when approving cranes. OES also recommended that the manufacturer reevaluate the design of the jib-turntable connection and that the tower tops be designed with a higher safety margin.

Engineering New Record has reported that the crane failures have been the subject of an ongoing lawsuit between the crane rental firms, the manufacturer, contractors, and developers. This report could potentially play a role in those lawsuits.