Even though the means to prevent trench collapses is pretty simple, dozens of construction workers continue to be killed by them every year. A few weeks ago, The Center for Construction Research and Training (CPWR) held a webinar on trenching and excavation hazards, the reduction of which is has been OSHA’s priority goal since 2018.

In the webinar, titled ‘Increasing Awareness of Factors that Influence Trench Safety, speakers discussed how OSHA enforces trench safety, results of an industry survey about trench safety, and alternatives to trenching.

OSHA’s Trench Safety Enforcement

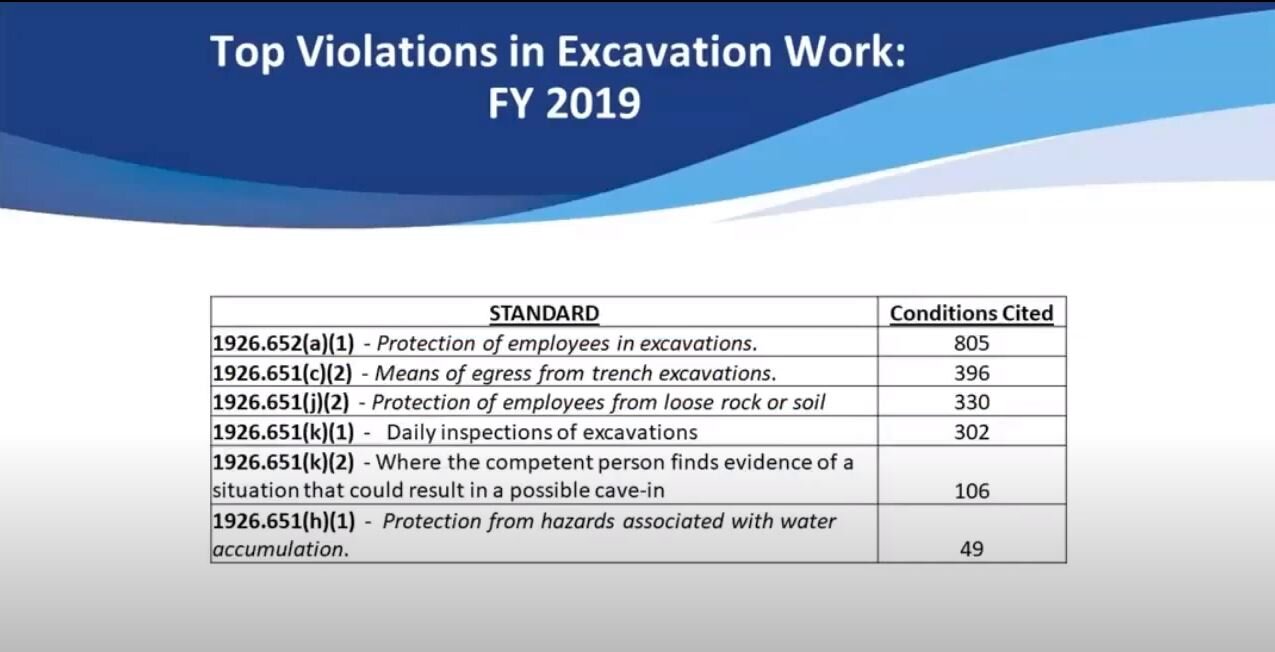

To speak about OSHA’s enforcement efforts, CPWR invited Scott Ketcham, the Director of OSHA’s Directorate of Construction. In OSHA’s 2019 fiscal year, standard 1926.651-.652 Specific Excavation Requirements was the 6th most frequently cited standard in the construction industry, accounting for 1,500 total violations, 1,173 serious violations, 35 willful violations, and 81 repeat violations.

via OSHA

Ketcham also broke down the specific standards that were cited for each of those violations. Standard 1926.652(a)(1) was by far the most frequently cited standard, which covers “protection of employees in excavations. That standard specifically states:

“1926.652(a)(1)

Each employee in an excavation shall be protected from cave-ins by an adequate protective system designed in accordance with paragraph (b) or (c) of this section except when:

1926.652(a)(1)(i)

Excavations are made entirely in stable rock; or

1926.652(a)(1)(ii)

Excavations are less than 5 feet (1.52m) in depth and examination of the ground by a competent person provides no indication of a potential cave-in.”

Other reasons for citations were means of egress, protection of employees from loose rock or soil, daily inspection of excavations, where the competent person finds evidence of a situation that could result in a possible cave-in, and protection from hazards associated with water accumulation.

via OSHA

In addition to the citation data, Ketcham also highlights fatality statistics, OSHA’s outreach training efforts, and additional safety resources. The full, 1-hour long video is embedded at the bottom of this article if you’d like to find out more.

Trench Survey

The 2nd speaker in the webinar was Joe Wise, Regional Customer Training Manager at United Rentals Trench Safety. In his portion, he discussed the results of a survey completed in conjunction with CPWR. An eye opening statistic from this survey showed that less than 25% of the respondents said that they frequently or always see trench protection on their jobsites. In addition, less than 50% of respondents said that there was always a competent person that was trained in trenching on their projects.

There were many other interesting results shared from the survey and this portion begins around the 25 minute mark in the video below.

Alternatives to Trenching

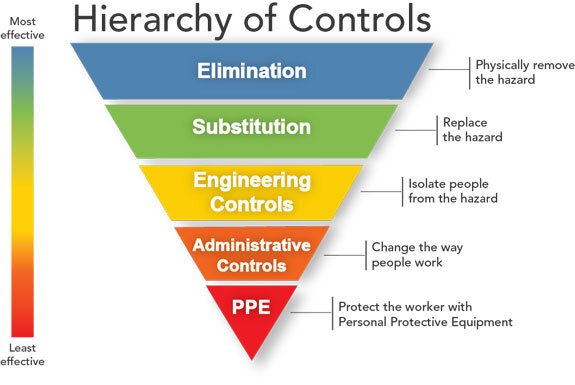

via NIOSH

The 3rd and final speaker of the webinar was CAPT Alan Echt of the NIOSH Office of Construction Safety and Health, who discussed alternatives to trenching. In the safety trainings that I perform one of my all-time favorite subjects to talk about is NIOSH’s Hierarchy of Controls. The chart highlights the effectiveness of certain categories of hazard controls are, elimination being the most effective and PPE being the least effective. Since trenching is unable to be eliminated in most instances, Echt instead focuses on the next best option: substitution.

Some of the alternatives to trenching discussed include directional boring, relining using cured-in-place pipe, pipe ramming, and utility tunneling and pipe jacking. Echt’s portion of the webinar begins around the 40 minute mark in the video below.

Shane is the creator of Construction Junkie and an active construction project manager. In his career, he has managed interior remodel projects, site development, construction safety, governmental project compliance, and facility maintenance. He has a strong passion for construction technology and safety, as well as sharing the knowledge or insights he has gained throughout his career.