Cranes is easily one of the most fascinating pieces of equipment on any large construction project and operators certainly have a unique view of the jobsite. So with that birds-eye view perspective, their vital important to the success of each project they’re on, and their relatively high cost, it only makes sense to collect data from cranes to make better business decisions.

I was recently introduced to a relatively new hardware and software solution from Versatile.ai called CraneView. Using an externally attached device directly to the crane’s hook, CraneView measures the load, weight, and motion of any material lifted, as well as tracking the time for rigging, unrigging, task, and idle time.

The CraneView hardware installs within seconds. Courtesy of Versattile.ai

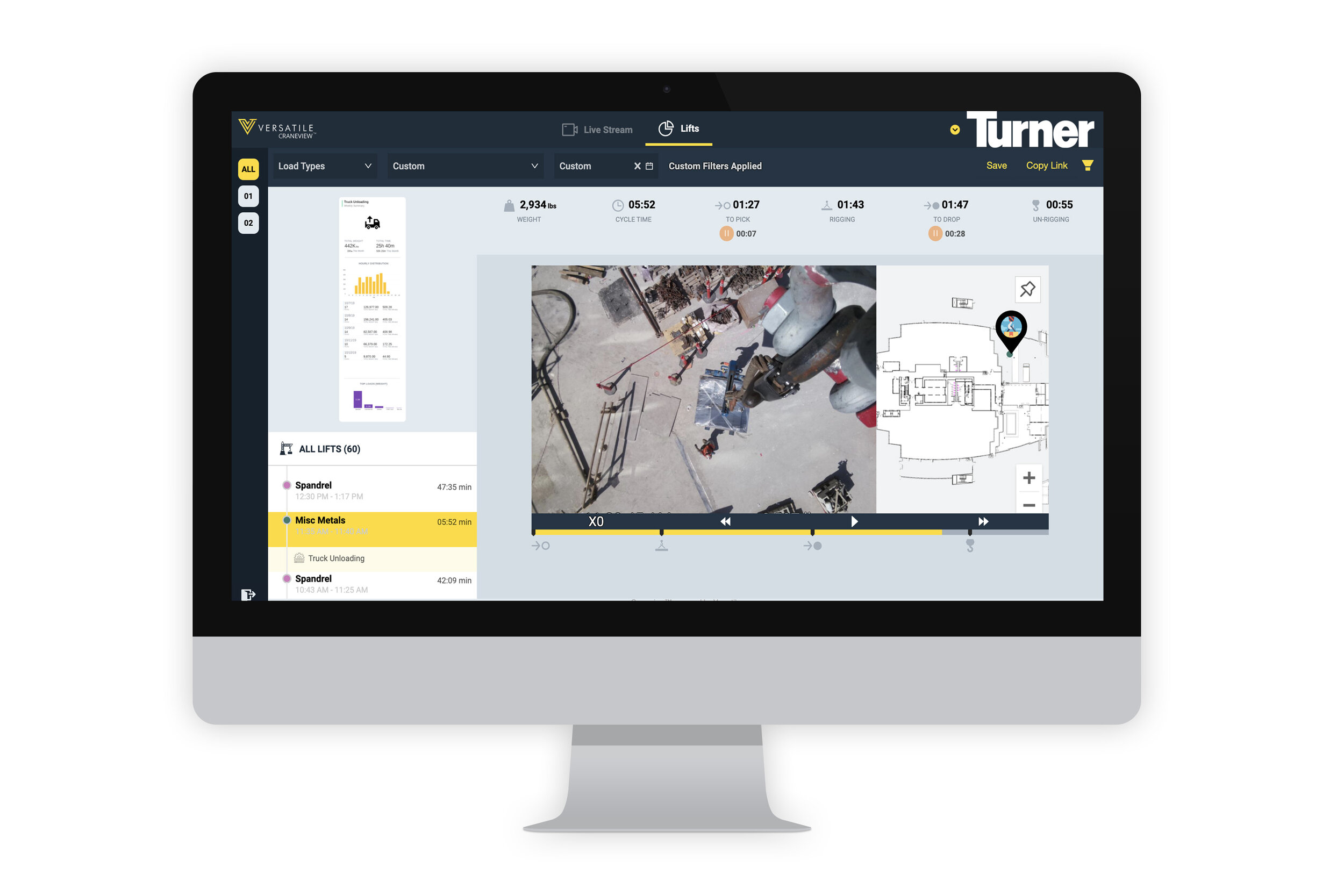

The CraneView hardware is equipped with a series of cameras and sensors so you can not only view each pick at a later time, but it also uses artificial intelligence to determine what the material being lifted is.

Since the device hooks directly on the crane’s hook, you might be curious about lifting capacity post installation. The company states that the device is “fully certified” and provides “the same weight capacity as the crane it is used on.” CraneView has also been used on over 300,000 picks so far.

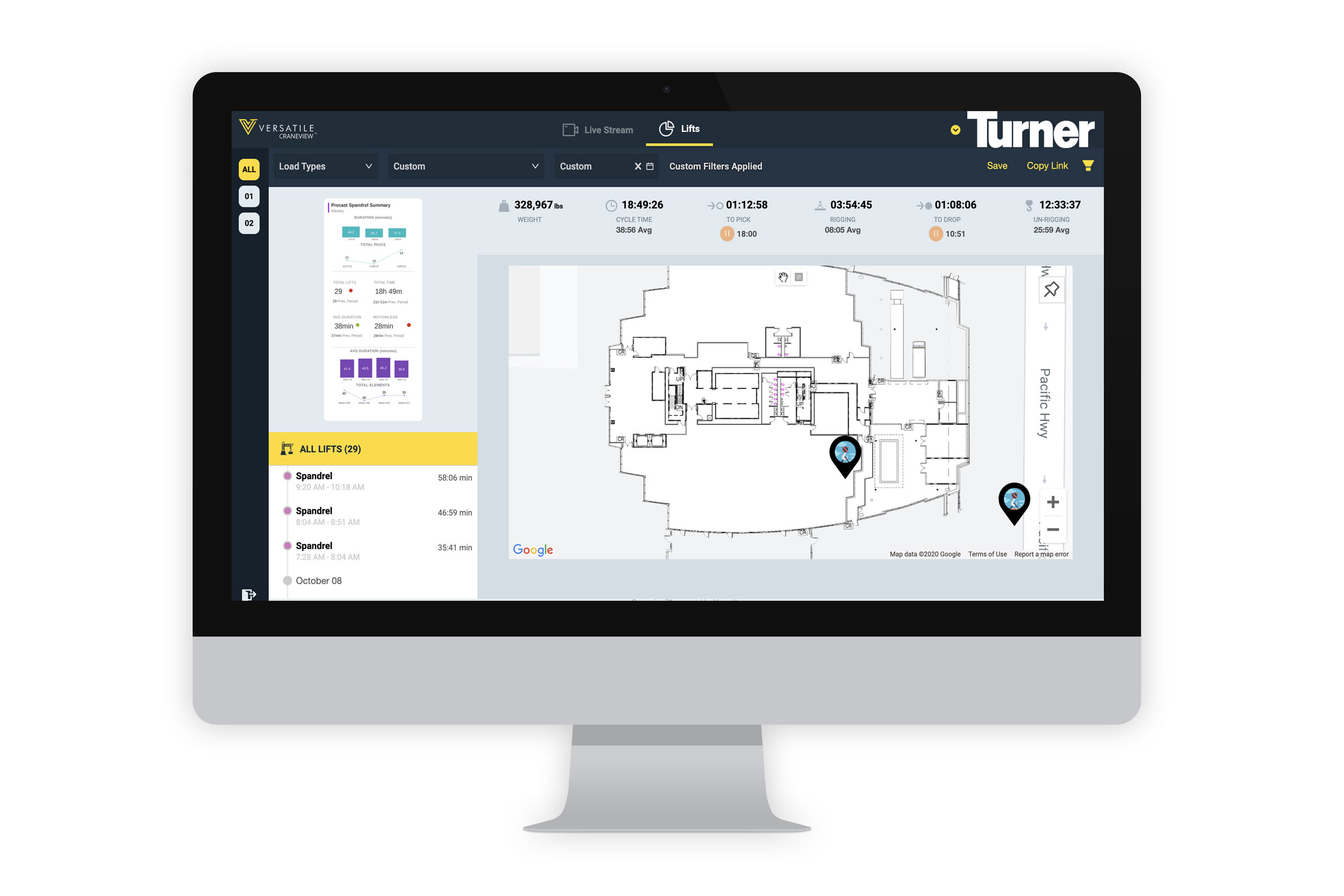

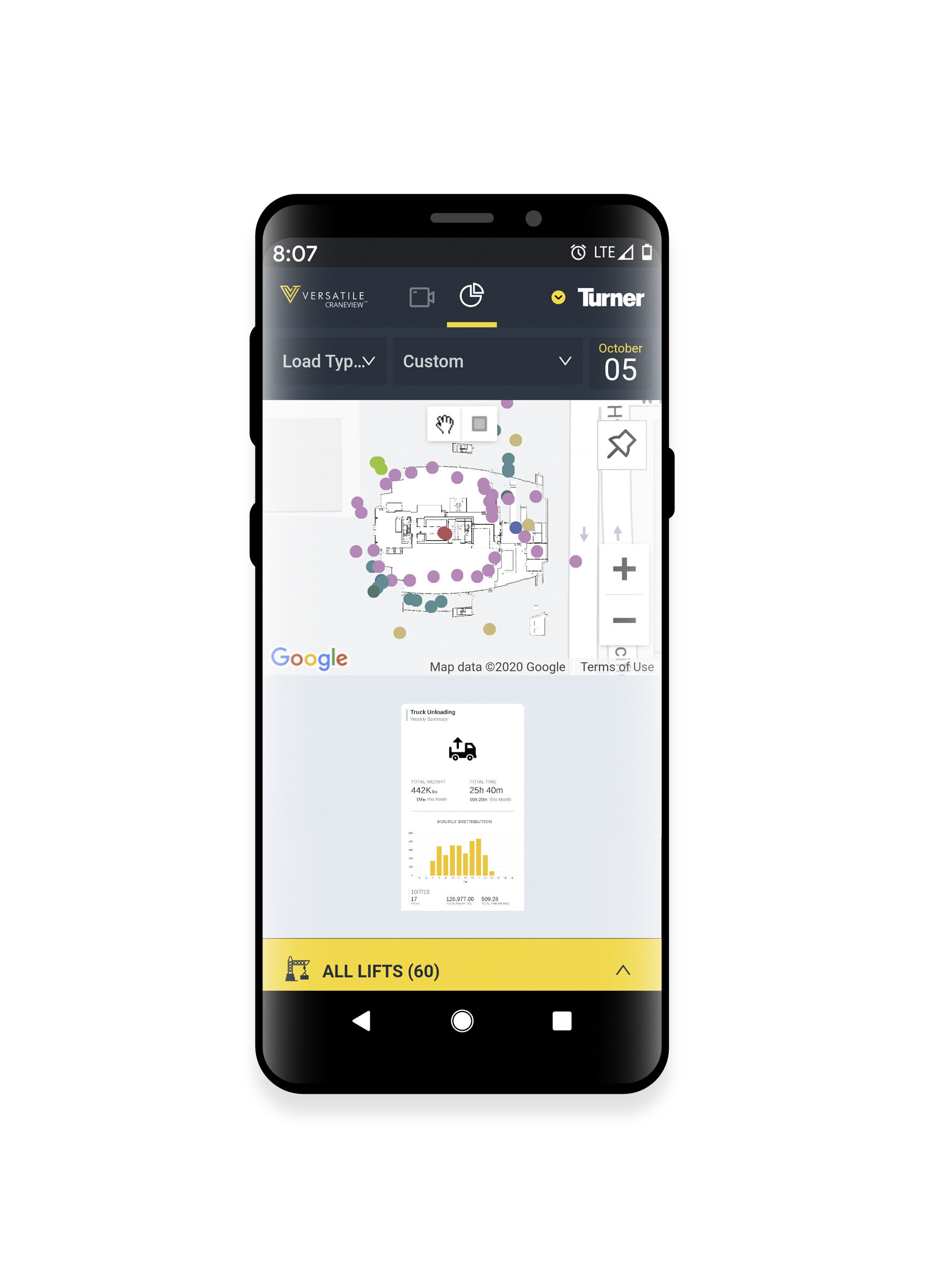

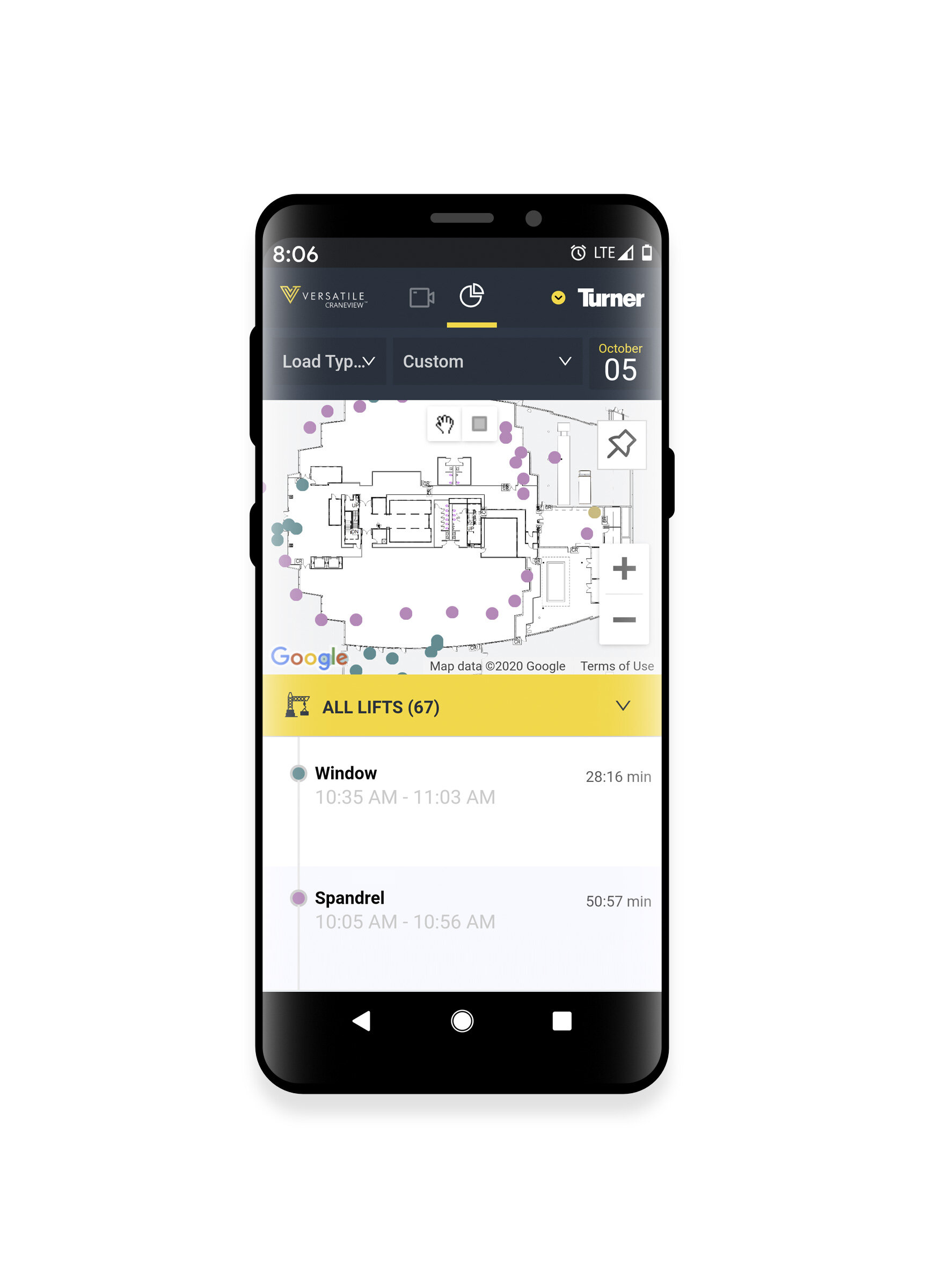

The hardware is only one side of the story, though, as the real value comes from the data collected and the software that compiles that data into meaningful charts and graphs. Available in both web and mobile view, these charts help the project management team to determine where their inefficiencies lie. Versatile.ai also touts the fact that their software doesn’t require a ton of additional work to manage.

Contracting giant, Turner Construction Company, has been using CraneView on some of their projects and has seen some considerable productivity gains. The firm piloted the technology on a 378,000 square foot project in San Diego, California for the US Navy. Using the data from CraneView, the project team was able to remove 17 days from the schedule. For a piece of equipment as expensive as a tower crane, that could not only result in some considerable monetary savings, but also some serious relief to the project schedule.

A typical pick from a tower crane may only have a 5-10 minute cycle time, but being able to reduce downtime by relocating material storage points, changing the position material is stored in, or even monitoring the fatigue of the workers rigging the crane can shave a significant percentage off of that time. Even reducing each pick by a minute will add up across hundreds of picks throughout the project.

“Once the system began compiling and analyzing real data, the value became exceedingly clear,” said Steve Elliot, Senior Project Superintendent for Turner, in a press release, “the insights we received led us to make data-driven decisions that positively impacted our productivity.”

Of course, as Elliot mentions, the data collected is only part of the picture. In order to grain real value with any piece of technology, you have to proactively use the insights gained to make impactful decisions in the field.

Shane is the creator of Construction Junkie and an active construction project manager. In his career, he has managed interior remodel projects, site development, construction safety, governmental project compliance, and facility maintenance. He has a strong passion for construction technology and safety, as well as sharing the knowledge or insights he has gained throughout his career.